Product

Location: Home>PRODUCTS>Potato chips processing equipment>China Big Factory Good Quality Frozen Potato French Fries Production Line

China Big Factory Good Quality Frozen Potato French Fries Production Line

Brand:

Spec:

Scope:

Application

Frozen french fries

Fried sweet potato chips

Introduction of Automatic Frozen French Fries Production Line

This is a perfect production line to produce good quality frozen French fries. Our frozen French fries production line has become the most popular product both in domestic and abroad. It enjoys the advantages of high automation, simple operation and energy-saving

Advantages of the Automatic Production Line

All equipment is made of high quality stainless steel, up to health standard, easy to clean

Improved productivity with excellent product quality

Low edible oil take up

Full automatic, very low labor requirement

Intelligent temperature control, low electricity consumption

Products tastes good and health

Capacity

French fries:

Semi-automatic line 50kg/h,100kg/h,200kg/h

Full automatic line 300kg/h,500kg/h,1000kg/h,2000kg/h

Chips:50-300kg/h

Banana chips:50-500kg/h

Flowchart of Automatic Frozen French Fries Production Line

Potato washing and peeling machine: It has emery-lined type and brush type as your reference. Integrating the function of washing and peeling, the potato washing and peeling machine can be used for processing potatoes, carrots, cassava and other root vegetables

Potato strips cutting machine: It is used for cutting the potatoes into strips and also suitable for other root vegetables, like carrots, cassava etc. The potato strip cutting machine is so flexible that the thickness of the potato slices or the size of the potato strips can be adjusted at your will

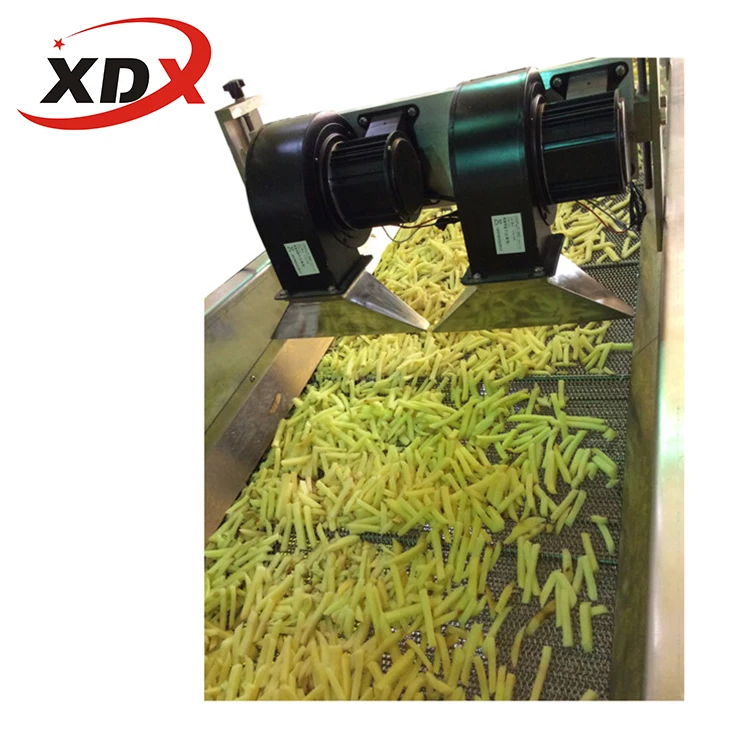

Potato blanching machine: The stainless steel blanching machine is of advanced design. The blanching temperature and time can be adjusted based on the processing capacity. The main purpose of blanching is to remove potato starch, ensure the potato strip brightness and crispy

Potato dewatering machine: It used to remove the surface water in an efficient way. This step is prepared for the frying part, which shortens the frying time and perfects the taste of the French fries

Potato frying machine: The whole frying machine is stainless steel. On the one hand, the oil level can be controlled automatically. On the other hand, an advanced set is equipped with the discharge flue, to avoid influencing French fries flavor. Besides, please notice that the frying oil should be pure edible oil and the frying temperature is170℃

French Fries de-oiling machine: It is designed to remove the spare oil and ensure the French fries more healthy. The vibrating process of the French fries de-oiling machine can speed up filtering process.

Frozen French Fries freezing machine: It is used for freezing the French fries, the feeding temperature is at 15℃ and the outlet temperature is at -18℃

French Fries packing machine: The packing machine should suitable for packing frozen french fries, to keep food fresh, tasty and without damage

Detailed Images

Packaging & Shipping

We use plywood box to transport our machine ,ensure that our products' safety and quickly.

Prev:IQF Frozen french fries production line

Next:small scale banana chips production line

Time:2020-11-30 08:22:27